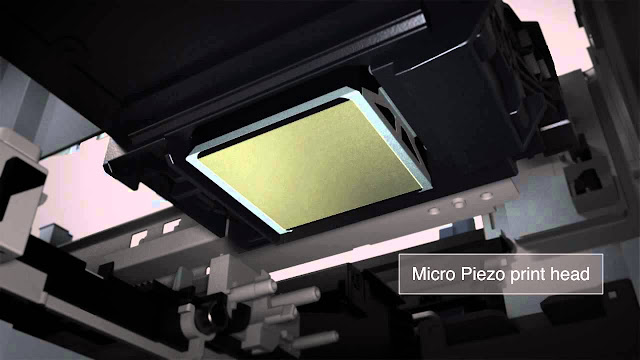

How does Epson’s Micro Piezo print head work?

In the Epson Micro Piezo print head, microscopic piezoelectric elements (like crystals and ceramics) are built behind the print nozzles. When an electrical charge is applied to them, these elements bend backward, forcing precise amounts of ink onto the substrate (see Diagram 1). Because electrical charges can be turned on and off like a switch, there is a vast amount of control over the rate of ink being ejected through the nozzle while also creating perfectly spherical dots at different droplet sizes.

Different from Piezo print head, there is another print head, thermal print head, what the comparison between them?

Different from Piezo print head, there is another print head, thermal print head, what the comparison between them?

Piezo print head:

Pros:

Pros:

Website:www.skyimagepaper.com

Company Name: Fei Yue Paper Industrial Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-83228884

Whatsapp: +86 18252072197

Address: Central Road 323, Nanjing, Jiangsu, China

Different from Piezo print head, there is another print head, thermal print head, what the comparison between them?

Different from Piezo print head, there is another print head, thermal print head, what the comparison between them?Piezo print head:

Pros:

- Precise and Variable Droplet Sizes

- Can use wide range of inks due to low temperature (solvent, UV, pigment, dye)

- Droplet sizes down to 1.5 picoliter

- Run longer due to cooler temperature

- More Expensive Heads

- Fewer Print Heads Per Printer

Pros:

- Less Expensive Print Heads

- More Print Heads Per Printer

- Only 2 different droplet sizes

- Larger droplet size

- Limited ink options due to extreme heat

- Need to be replaced more often due to high heat

Website:www.skyimagepaper.com

Company Name: Fei Yue Paper Industrial Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-83228884

Whatsapp: +86 18252072197

Address: Central Road 323, Nanjing, Jiangsu, China

评论

发表评论